This brochure will explain the WFI and/or NOFMA trademark/certification process for how to install hardwood flooring. This specific process for hardwood floor installation involves precision, expertise and skill by a flooring company, and promises a product of enduring beauty.

Please keep in mind, however, that the final appearance and performance in any application, depend upon the installer and his or her attention to detail. You want to be sure to hire a flooring contractor who has experience in the field and whose customers have given positive reviews of the hardwood flooring service.

This manual provides the simplest methods for achieving a successful hardwood floor installation, based on many years of practical experience. The instructions here describe methods to be used with various types of oak, bamboo, maple and other types of hardwood flooring.

While the information we provide is universal enough to apply to most hardwood flooring types, it is important to always read and follow instructions as they are given to you by a manufacturer for your specific hardwood flooring. Manufacturer instructions will vary, and individual companies may provide instructions which vary from those you see here, particularly in the laying of specialty hardwood flooring.

Before beginning any hardwood flooring installation project, please read this entire manual. If you happen to come across a situation that has not been addressed here, you can contact the Technical Department of NOFMA for assistance. Call (901) 526-5016 for general information and to have questions answered. The office is open between 8:30 a.m. and 4:30 p.m. Central Time, weekdays.

Please remember that this brochure only contains information about hardwood flooring installation methods. If you would like to learn more about hardwood flooring finishing procedures, please request a separate manual from the WFI.

NOFMA 9 HARDWOOD FLOORING NOFMA/WFI TECHNICAL SERVICE HANDLING AND STORAGE FOR HARDWOOD FLOORING INSTALLATION

Solid hardwood is the best for floors that are on or above ground level. These types of flooring options are ideal for the Chicagoland area. This flooring type is very durable and long lasting, and can be refinished and re-coated over years. However, if you are the type of homeowner who enjoys the rustic look of minor dents, cracks and scratches in your flooring to add character to your home, you may prefer to leave them be. Solid hardwood shrinks and expands depending on the level of humidity, so it is very important to keep temperatures and humidity levels in your home to around 40% for the entire year. In order to achieve this, you may want to run a humidifier in the winter time, and the air conditioner on during the summer time.

Store kiln-dried hardwood flooring in an enclosed building with weather-proof windows that is well ventilated and located in an area where similar fine millwork is stored. The storage area for the prefinished or unfinished hardwood flooring should be clean and dry. Leave adequate room for good air circulation around the bamboo, oak, cherry, walnut or white oak materials. Remember that over-heating hardwood flooring with continual dry heat may dry out the hardwood flooring too much. This could lead to buckled hardwood flooring later on, due to hardwood flooring delivery and installation without proper spacing or acclimation.

JOB SITE CONDITIONS FOR FLOOR CONTRACTORS

It is a best practice to check every job site before delivery of hardwood floor installation materials have been placed in the scene. You want to avoid extended exposure to high humidity or moisture. Ideally, the surface grade or slope of construction of the job site should direct water away from the building. Only use basements and crawl spaces which are dry and well-ventilated. If a joint construction site has no basement, you are required to use outside cross ventilation through vents or other openings in the foundation walls with no dead air areas. To hinder the presence of vapor in crawl space construction at a flooring site, use a surface cover of 6 mil polyethylene film. This type of film can be bought online or at most home and garden stores.

When executing the job, please keep in mind that the building of the job site needs to be closed in. Outside windows and doors should be fixed in place. Before delivering hardwood flooring materials, all concrete, masonry, sheetrock and framing members, etc. should be thoroughly dry, especially in an area like Chicago where temperatures vary greatly depending on the time of year. You will need to carefully control temperatures and ventilation of the job site. In warm months, the building must be well-ventilated; during cold months, heating should be kept near occupancy levels. Do this for at least five days before the flooring is delivered and until dustless floor sanding and hardwood floor finishing are complete.

You may need to delay delivery and installation of flooring to allow any moisture trapped during construction to evaporate. As most professional flooring contractors know, excessive dampness can accumulate in a residence due to materials used to provide energy efficient structures trap moisture. Before delivery of hardwood flooring materials, the average moisture content of framing members and subflooring should be below 12-14 percent. Levels above this can cause aesthetic issues for hardwood floor installation and hardwood floor refinishing.

Once you have confirmed that job site conditions adhere to these standards, the next step would be to deliver the hardwood flooring materials. It is wise to not pile up all the materials in one spot, but to scatter the materials into small groups and to store them in specific rooms where the hardwood floor installation will occur. The next step would be to wait four to five days (sometimes more) for the flooring to acclimate to the job site.

Next, open or remove packaging of any hardwood flooring materials so that they can adjust to the local environment. After delivery, temperature and humidity should be maintained at or near occupancy levels until the hardwood flooring installation takes place. Continue to control the environment even after occupancy in order to avoid elevated moisture conditions. This is important in order to maintain a beautiful finish of your hardwood flooring after installation is complete.

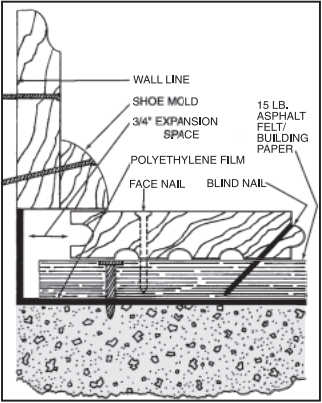

Another tip is to keep hardwood flooring away from excessive heat. You may see cracks appear in hardwood flooring if it’s installed over a heating plant or un-insulated heating ducts and no protection is provided. Adequate protection can be created if you use a double layer of 15 lb. asphalt felt/building paper, or a single layer of 30 lb. asphalt felt/building paper. Another option for your hardwood flooring is to use 1⁄2" standard insulation boards between joists under the flooring in the areas where heat is applied. If the hardwood floor installation happens over a heating plant, the insulation used should be non-flammable. As a flooring contractor, it is your responsibility not only to provide a high-quality product to your customer but also to ensure safety in their home. Wood floor installation is an intricate process. Be sure to consult this guide or call the Technical Department of NOFMA for extra help.

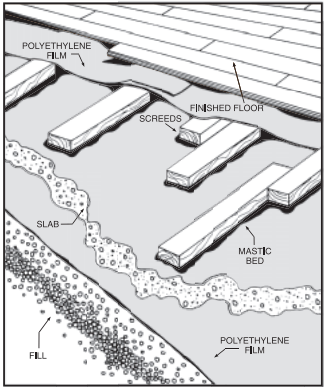

HARDWOOD FLOOR INSTALLATION OVER A CONCRETE SLAB

You can successfully install hardwood flooring over a slab which is on-grade or above grade. We do not recommend below-grade hardwood floor installations. Be sure the slab has been constructed properly (check that it is dry and flat with a trowel finish). Keep an eye out for water when you are getting ready to install the wood flooring. New concrete tends to be very full of moisture, which is wood’s worst enemy. The last thing you want to do is ruin a beautiful piece of cherry, maple or white oak wood simply by forgetting to accommodate for moisture in the on-grade concrete slab. Proper on-grade slab construction requires the use of something to hold back vapor. Usually 6 mil polyethylene film is placed between the gravel fill and the slab. This not only prevents moisture from entering through the slab, but the membrane also curing of the slab. Even if the slab has been in place for over two years, test it for dryness. If a slab is younger than 60 days old, it’s probably still too wet for flooring installation. Keep this timeline in mind when you are planning a hardwood floor installation project so your client understands the amount of time it will take to complete installation.

TESTING CONCRETE FOR EXCESSIVE MOISTURE

NOTE: Test both old and new slabs in several areas of each room where the wood flooring is going to be installed. If a test indicates there is too much moisture in a slab, do not proceed with hardwood floor installation. You have several options if a wet slab prevents hardwood flooring installation from proceeding. You can wait until moist slabs dry naturally, or accelerate drying with heat and ventilation and then test the slab again.

Here are several tests you can use to test a slab for moisture.

- The Rubber Mat Test. Lay a smooth, non-corrugated rubber mat over the slab. Place a weight on top of it to prevent moisture from escaping. Leave the mat in place for 24 hours. If the covered area shows water marks when the mat is removed, the mat is too wet to begin hardwood floor installation.

Note: you should not use this test if the slab surface is not light in color originally because you could detect false water marks. - The Polyethylene Film Test. Cut out a one-foot square of 6 mil clear polyethylene film and tape it to the slab, sealing all edges with plastic, moisture resistant tape. After 24 hours, if there is not any visible “clouding” or noticeable drops of moisture on the underside of the film, the slab can be considered dry enough to proceed with the hardwood flooring installation process.

- The Calcium Chloride Test. Place 1/4 teaspoon dry (anhydrous) Calcium Chloride crystals inside a 3-inch diameter putty ring. Place on the slab. Cover the putty ring with a glass so that the crystals are totally sealed off from the air. You’ll know the slab is still too wet if the crystals dissolve within 12 hours.

- The Phenolphthalein Test. Create a solution of a 3% Phenolphthalein solution in grain alcohol such as ethanol. Place several drops at various spots on the slab. If a red color develops in a few minutes, there is too much moisture present in the slab. You must wait to begin hardwood flooring installation.

It’s important for every professional flooring contractor to practice and understand these tests in order to ensure hardwood flooring installation that avoids moisture. For your Chicago area wood flooring needs, contact Great Flooring, Inc.

SLAB PREPARATION BEFORE WOOD FLOOR INSTALLATION

Be sure the slab is sound and flat. Grind off any high spots and fill low spots so that the surface is smooth. Remember to clean up grease, oil or any other contaminants, and sweep clean. If the slab feels mealy or gritty, or if its texture is excessively dusty, it may not be of proper strength.

VAPOR RETARDER USE OVER A SLAB

Proper vapor retarders must be used on top of every slab to ensure moisture does not reach the finished floor. It is your responsibility as a flooring company to know which vapor retarders are appropriate for the hardwood flooring job.

Where you place a vapor retarder depends on the type of system used. Check that the vapor retarder has a U.S. perm rating of less than 1 perm. You will often see 6 mil polyethylene film used since it has a 0.04 perm rating which is considered a good choice. The recommended vapor retarders are affixed to the slab with 3⁄4" plywood which is used as a nailing base. These systems can either be a 4-6 mil polyethylene film, 2 membrane asphalt felt/building paper and mastic, or an equivalent system as described below.