Hardwood Floor Installation Chicago

Quality floors are an investment just like any other repairs or additions you do to your home. It has become an essential requirement for most homes and businesses. With the proper installation and maintenance, hardwood floors can last a lifetime, and extend the value of your home. There are many options to explore when selecting the proper type of wood flooring Installation for your home. All of these options can be overwhelming without some experience and knowledge.

Our expert technicians are ready to perform any type of installation from wood flooring to vinyl Plank Flooring, from laminate flooring, to engineered hardwood flooring. We offer services in residential and commercial settings and will come to you for a free estimate, since we do not have a showroom for our customers. We like to give you the personalized touch and will evaluate your floor installation needs,giving you an itemized, detailed Proposal of your new hardwood floor installation project.Our hardwood floor installers are highly trained professionals who do stellar work. Great Hardwood Flooring is an Expert in prefinished and unfinished hardwood floor Installation; We have been serving Chicago and surrounding suburbs of the greater Chicago metropolitan area, for more than 20 years now. And being in this field for a long time gives us a straightforward perspective to know our customer's needs and exact requirements. That is why we are one of the best rated hardwood floor installation companies in your town, and you will definitely love our work.

We offer a wide range of flooring types of installation. Great Hardwood Flooring partners with the local hardwood flooring suppliers. They provide us with the best material and the extensive range of flooring as follows : solid oak flooring, Wide plank flooring, Floating Engineered flooring , Maple Flooring, Brazilian cherry , White Oak Flooring, Red Oak Flooring, Birch and many more that exactly matches your requirements and expectations. Let us show you some of the best methods we use to get your floor installation done.

- Labor construction

- satisfactory warranty

- thickness

- number and type of finish coats

Let us show you some of the best methods we use to get your floor installation done.

NAIL DOWN WOOD FLOOR INSTALLATION:

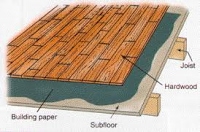

In this method we nail down or staple solid unfinished, per-finished or engineered wood strips to the sub-flooring (usually either plywood or plank wood). Using standard 15 gauge Staple or 16-Gauge Power cleats( Hardwood Flooring Nails). The floor is completed with random length strips. Creating a staggered pattern that is usually A few strips are placed down and arranged prior to fastening, to ensure proper placement and tautness we need to make sure that the boards are placed in crossing direction to the joist and need to be stapled less than 7 inch between each other. We also need to make sure that the distance between adjacent joints need to be at least 6 inch or more

GLUE DOWN FLOORING INSTALLATION:

In this method, we use another popular technique that is to glue down the floor. We glue down the engineered wood strips directly to the subfloor. The important part is to take care of moisture as, in most cases, the floor is made of concrete. But our team takes care of that for you. So you do not have to worry about it at your end.

So it is also very important to take care of any sensitive smell that might cause any kind allergies. Our experienced team members use acrylic-based glue, which is quite mild in smell. And if you compare it to the other adhesive, you will find it pretty strong and mild in smell. So it also prevents you from having any kind of allergies.

And the best part of the installation is that you can even utilize the floor very next day of installation, which is the fastest way of utilizing the time.

So if you are setting up a business and want to change the flooring in your existing flooring, you should consider this option so your business will not have to stop for countless hours to move furniture in and walk on. And that is an amazing thing to consider.

FLOATING HARDWOOD FLOOR INSTALLATION :

Wood moisture:

It is quite important to know that its moisture content measures the durability of hardwood floors. Some types hold about 200% water moisture of its wood weight. And when the wood is cut, it is then stored in a room with about 30% humidity level. So this is the level at which woods stay stable. Anything below or above this level might cause the wood to swell or shrink, which is not a good thing.

So it should be really taken care of before the installation process, this is to reduce to risk of moisture damage. We are qualified in handling the wood carefully; that is why our flooring is durable and gives you long-lasting durability. It is also important to note down the temperature of the climate and your room temperature. A perfect-fitting requires attention to detail so that you can enjoy your best hardwood flooring.

If you hire someone who does not have enough knowledge in this field, it might mess things for you in the long run as there are many things that should be taken care of. And only an expert with relevant field knowledge can give you that.

Let us discuss some of the types of flooring.

Flooring types

Solid: Solid constructed wood floor varies from ¼" to 25/32" and some of the products of 1". It has a wide variety and flexibility of customization. So if you want customization, then solid flooring would be the best option for you. The solid flooring is also perfect for your home for most of the areas on the ground level or above.

You can even use sanding with solid hardwood flooring to resurface the hardwood flooring.

Engineered hardwood flooring:

These types of hardwood flooring come in different layers. With grain alternating, you have more flexibility in them for installation. And this is especially best to install where the solid wood floor cannot have flexibility as these have more flexibility.

This product has various ply's (the layers) that come with 3 to 5 layers. It can be treated as both with glue or with the nails. And it also gives it the flexibility over the top of radiant.

Laminate:

Laminate flooring is also very popular; it is a base of MDF, Medium Density Fiber Board, and that is with a computer-generated image of wood flooring on top.

These types are quite famous and can be used anywhere. They are guaranteed to durability against water. The wood is floated over foam or the color underlay, and that looks absolutely beautiful.

So, if you also love the beauty of laminating flooring, then you can contact us, we have our expertise in the installation of best lamination flooring.

Strip:

It is also a famous type that uses wood flooring with lineal tongue and groove construction, and it is mostly 1.5” inches to 2.25” inches.

Plank:

It is almost the same as the strip flooring except for the one difference that is its width that starts from 3” inches to 3.25”. Some varieties can go up to 12” to 14” inches in solid or engineered hardwood flooring.

Parquet:

It is definitely one of the best and most famous types. It uses the patterns on it. The construction uses designs that look stunning and pretty attractive. They are geometric in nature, and this type of flooring uses glue to the sub-flooring and can be unfinished and pre-finished.

These were the flooring types you can definitely visit our official website, Great Hardwood Flooring, and give your quote. We will give you the best price along with the best service. Our staff and team are highly skillful in carrying out any kind of hardwood flooring work.

We are based in Chicago, Illinois, and we will be happy to hear from you.

Nail Down/Staple: Unfinished and Pre-finished Wood Floor Installation

In this method we nail down/staple solid unfinished, pre-finished or engineered wood strips to the sub-flooring (usually either plywood or plank wood). The floor is completed with random length strips. A few strips are then placed down and arranged prior to fastening, to ensure proper placement and tautness.

Glue Down Flooring Installation

In this method, we glue down the engineered wood strips or parquet directly to the sub-floor. In most cases the sub-floor is usually concrete, so our team pays extra attention to moisture. With glue down installations, it is important to consider any kind of allergies and sensitivities to smell. We use an acrylic based glue which is more mild than other forms of adhesives. This glue down method for flooring can be accessible and walked on the next day of installation, and furniture can be moved in next day.

Nail Down/Staple: Unfinished and Pre-finished Wood Floor Installation

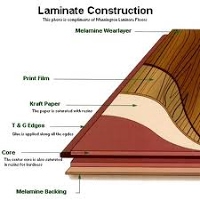

In this method, we glue together the tongue and groove of every plank. The floor floats over a foam cushioned padding, which helps with stability. If the flooring has a locking system, our team can lock the pieces together without adhesives. This can be used with either laminate or engineered wood floor, but, in each case, the flooring is pre-finished. However, not all engineered surfaces can be floated. Floating wood floor installation can also be placed over sub-flooring of questionable quality, unlike the other two modes of installation. Also, floating wood floors are a great option if you have multiple layers of flooring and do not want to remove them all. With the floating wood floor installation option, the wear layer is important to consider as the thicker the layer the more the hardwood floor can be refinished. Another advantage to laminate flooring is that it generally gives a hollow feeling underfoot. Remember that floating floors expand and contract as a unit because the pieces of fused together, so it is wise to allow for as much expansion area as possible.

Our wood floor fitting service and hardwood flooring installation comes with an ultimate attention to detail focused on durability and utmost quality. We never cut corners or retain our advice on proper floor preparation before laying hardwood flooring or putting the final layer of your parquet, solid wood or engineered wood floor. Our flooring experts partner with leading industry suppliers of oak flooring and offer an extensive range of flooring materials, skirting, beadings and insulation to match and surpass your expectations..

If you are looking for professional flooring installers, please contact Great Flooring Service Inc. We will be more than happy to help you with your Hardwood Flooring project. Our company provides Professional Wood Floor and Tile Services, Dustless Sanding, Custom Staining and Sealing, Refinishing of existing wood floors without the dust, Marble Tile Installation, Installation of Granite Tile, Hardwood Stair Refinishing and Installation of Wood Work Designs .

Trust Professional wood floor installation company

Call Great Flooring Service, Inc.

708-369-3372

It is important to understand where certain types of hardwood flooring can be used, in order to select the flooring that is right for you. With this approach, your flooring is more susceptible to lasting a lifetime. Our Illustration below (to the right) exemplifies an idea in which location products can and cannot be used. The brown area represents the soil line from your foundation, and red shows common floor joist systems.

Wood Moisture:

The durability of hardwood floors is measured by its moisture content; in other words, the amount of water a particular woocan carry. Some types can hold up to 200% of its actual wood weight! Once the wood has been cut, it dries and is typically kept in a room with a 30% humidity level. At this level, most wood are very stable. Any change below or above 30% may cause wood to either shrink or swell.

Preventative measures should be taken before and during the installation process in order to reduce the risk of moisture damage. Letting your floors acclimate and adjust to your home environment is an essential part of the process. Allowing your wood floors to stabilize will help ensure less floor movement during and after installation.

Acclimation could take anywhere from a few hours to a week, depending on climate and temperature of your home, as well as the moisture content of the wood

RELATIVE HARDNESS OF SELECTED WOOD FLOORING SPECIES

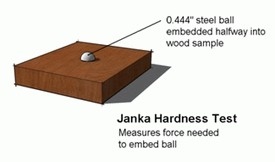

Table (Janka) For Domestic & Exotic Wood Flooring Species:

The diagram below is a measure of the rigidity of wood, produced by a variation on the Brinell hardness test. The test measures the force required to push a steel ball with a diameter of 11.28 millimeters (0.444 inches) into the wood to a depth of half the ball’s diameter (the diameter was chosen to produce a circle with an area of 100 square millimeters). In Janka's original test, the results were expressed in units of pressure, but when the ASTM standardized the test (tentative issue in 1922, standard first formally adopted in 1927), it focuses on results in units of force.

The results are stated in various ways in different countries, which can lead to confusion, especially since the name of the actual unit employed is often not attached. In the United States, the measurement is in pounds-force. In Sweden it is apparently in kilogram-force (kgf), and in Australia, Janka hardness ratings are either in newtons (N) or kilonewtons (kN). Sometimes the results are treated as units, e.g., “360 janka.”

The hardness of wood usually varies with the direction of the grain. If testing is done on the surface of a plank, with the force exerted perpendicular to the grain, the test is said to be of “side hardness.” Side hardness of a block of wood measured in the direction of the tree's center (radially), and on a tangent to the tree's rings (tangentially), are typically very similar. End testing is also sometimes done (that is, testing the cut surface of a stump would be a test of end hardness). The side hardness of teak, for example, is in the range 3730 to 4800 newtons, while the end hardness is in the range 4150 to 4500 newtons. The most common use of Janka hardness ratings is to determine whether a species is suitable for use as flooring. We show the common name preferred by the Forest Products Laboratory. Except as noted, all samples were tested at 12% moisture content, typical of air-dried wood. Wood varies; a sample picked at random is expected to have a side hardness between about 80% and 120% of the value shown. Blank cells occur where a wood is sold commercially but so far we have found no hardness

Engineered hardwood flooring

Wood Flooring products constructed in various layers, with grain alternating in opposite directions give this product more stability for installation in areas where solid wood floor products can not be installed. This product comes in various ply's ( layers), most being 3-5 ply. Also, the engineered wood slabs can be nailed OR glued, which allows it to be used over the top of the radiant (in floor) heating systems without problems. This type of hardwood flooring can be installed as a floating floor.

Laminate

Is a base of MDF - Medium Density Fiberboard with a computer-generated image (picture) of wood flooring on top. The positive aspect to laminate is that it can be used anywhere, and everywhere. Majority of these flooring styles are guaranteed against water damage, and other dangers that affect wood. The wood is floated over a foam or cork underlay, which allows the floor to move easily. The floors are 'floated' which means that they are not attached to the sub floor, rather to each other (some with glue, others with a tension system that holds them together).

Strip

Wood flooring with a lineal tongue and groove construction most often in 1.5" and 2.25", solid or engineered, unfinished or prefinished.

Plank

Same as strip except for width variation. Most start at 3" or 3.25" and go up in width in 1" increments. Some varieties reach 12-14" in solid or engineered, unfinished or prefinished.

Parquet

Pieces of wood floor construct into a pattern or design, most often geometric in nature. Usually this type of flooring is glued to the sub floor, and can be unfinished or prefinished.

Hardwood floors are an investment that will last a lifetime with the proper installation and care. There are different modes of floor installation for engineered wood strips, solid wood strips, and parquet. With all modes of floor installation, moisture testing is imperative to ensure proper floor installation. Installation can be a painstaking process but we take pride in leaving your home making it even more beautiful than before. Our expert technicians have seen every situation and are proficient in the three different types hardwood floor installing .

Our comprehensive service ensures that no detail gets overlooked. We determine the temperature levels of the subfloor, as well as the presence of a moisture barrier and sound barrier to guarantee your satisfaction with the flooring installation.